- +61 7 3374 2877

- Email Us

It is a well-known fact that moisture in transformer paper insulation presents risks to transformers, be it by way of depolymerisation, breakdown voltage reduction or risk of bubbling (1). Conventional dry-outs of active parts are achievable and feasible for most power transformers used in the power generation industry.

It is a well-known fact that moisture in transformer paper insulation presents risks to transformers, be it by way of depolymerisation, breakdown voltage reduction or risk of bubbling (1). Conventional dry-outs of active parts are achievable and feasible for most power transformers used in the power generation industry.

However, in some instances, especially within underground Hydro power stations, there may be limitations and extra implications to consider. These limitations include transport, access, handling of the active part. There is also increasing pressure to limit outage durations.

In this article some key learnings and methodologies are documented with respect to two 66.67 MVA transformers located underground at Rangipo Hydro power station situated in New Zealand’s North Island alpine region. The units were dried out and the active parts re-clamped in-situ. No enclosure was built around the transformer and the tank was used as the vacuum chamber. As such the active part was never removed from the transformer tank. The method used for the dry-out was the so-called Low Frequency Heating (LFH) method, utilising a 900 kW thyristor based power conversion unit, developed, manufactured and modified by Pringle Beleski and Associate’s Ltd (PBA).

Background on the units

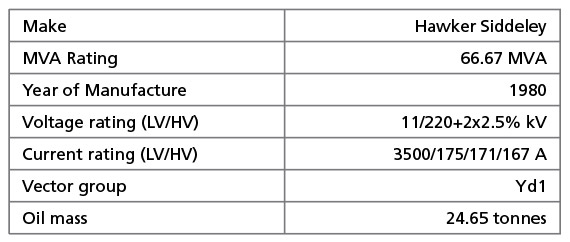

The two power transformers of concern are 66.67 MVA, 11/220 kV, Hawker Siddeley power transformers, used as Generator Step-Up transformers in Rangipo underground power station in New Zealand. They have De-Energised Tap Changers (DETC’s) with oil-to-SF6 bushings completing the interface into the underground Gas Insulated Switchgear (GIS) on the High Voltage (HV) side. These transformers were manufactured in 1980, with the Rangipo station being commissioned in 1983, making them 39 years old when the dry-out and re-clamping was undertaken from February to April 2019.

Details from the rating plate are provided in Table 1.

The general condition of the transformers was initially judged as good following internal inspections conducted in 2012 with the original replacement plan for the transformers around 2028, after almost 50 years of service. However, after a review of the Degree of Polymerisation (DP) testing conducted during the 2012 internal inspections, it was revealed the lowest DP result of samples taken on the Low Voltage (LV) lead outs was 569. Based on this result it was decided that there was an opportunity to perform a general overhaul on the transformers and this could lead to a possible life extension beyond 2028.