- +61 7 3374 2877

- Email Us

Photovoltaic systems are an increasingly popular way to convert solar energy into electricity. To maximise the efficiency and performance of photovoltaic systems, regular monitoring and maintenance is essential.

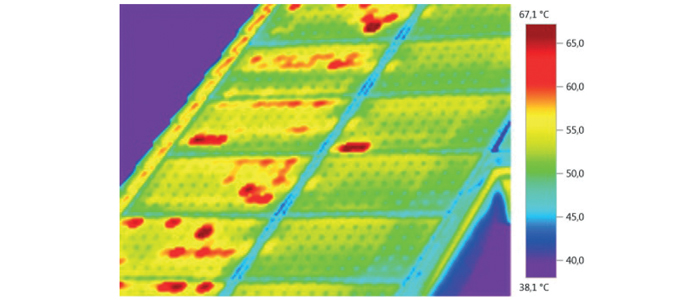

The best method for checking photovoltaic systems is thermography, which uses a thermal imager to record the temperature distribution on the solar cells. This allows faults and defects to be detected in good time, thus maximising the yield of the plant.

What are some of the other practical reasons for using Thermal imaging in these applications, see some of these listed below:

Avoiding Customer Yield Losses

A new photovoltaic is based on an extensive and detailed yield and investment analysis. For this purpose, yield and amortization are calculated for terms of up to 20 years. However, these calculations do not include power losses due to problems with modules, inverters and other components, or due to faulty installations.

With the use of thermography, it is possible, as early on as the commissioning stage, to produce acceptance documentation and provide proof of proper installation.

Regular inspections are indispensable to ensure sustainable yields for new and existing plants. If modules become heated due to dirt, shade or faulty cells, i.e. consume power instead of generating it, the efficiency drops by 0.5 % per Kelvin. An average temperature rise of 10 °C compared with the mean standard temperature means a 5% lower electricity yield.

Quality assurance and warranty

Using thermography, it is possible to check whether the quality of the module cells fulfils the requirements. The right combination of individual modules avoids so-called mismatches, where high-performance modules are impeded by “inferior” modules. With an inspection before the end of the warranty period, any warranty claims towards suppliers can be asserted in good time.

Safety of personnel during inspections

PV systems are live during daylight hours. In the case of modern module strings, voltages are often up to 1000V. This poses a considerable risk of electric shock for personnel. For this reason, thermography is a very safe inspection method, as recording thermal images is always done with the necessary distance to the measurement object. This means that safe distance requirements are easily met.

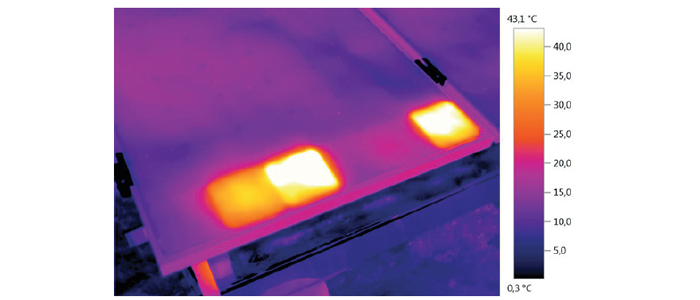

Fire protection

Fire protection is of increasing importance. Modern inverters and electrical components are becoming more and more powerful (high level of efficiency), however the resulting high level of heat emitted must also be taken into consideration. Incorrectly fitted or inadequately cooled electrical components can quickly pose a fire risk, particularly if the mounting base is made of combustible material.

Electrical components installed outdoors age especially quickly as a result of weathering and UV radiation. Corroded or loose electrical cables indicate thermal irregularities, which would show up on a thermal imager.