- +61 7 3374 2877

- Email Us

Diode Rectified Frontend (DFE) Variable Speed Drives (VSD) are increasingly adopted in a variety of industrial applications, yielding substantial savings on energy while providing the control needed to meet the ever-changing demand of industrial processes. VSDs control the torque and/or speed of an AC electric motor in applications such as fans in ventilation, motors in belt conveyors, rolling mills and water pump systems.

In high power rating, Diode Rectified Frontend VSD utilises a multi-pulse arrangement on the line-side rectifier stage. In this arrangement, a Phase Shift Transformer (PST) is connected on the line-side to produce a smooth DC link voltage. The number of pulse correlates to the number of ripples in the DC link per AC input cycle.

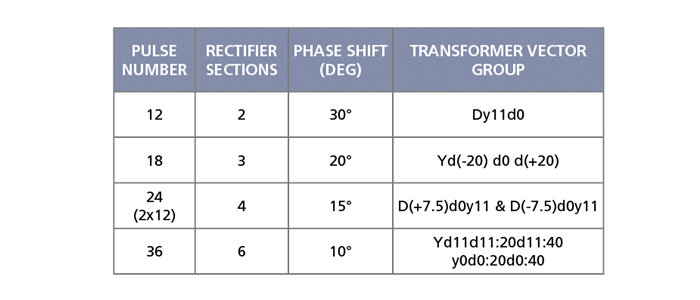

Phase Shift transformer can assist in mitigating the harmonics reaching the electrical network through the number of pulses of the VSDs. The harmonic distortion can be mitigated by increasing the number of rectifying sections used in the VSDs, as shown in Table 1. The larger the number of pulses, the smaller the distance between waves, which then create a shorter distance between wave crests and consequently lower harmonic distortion.

One of the Reasons Switchroom is Larger

Phase-shift transformers are specially designed electrical equipment that requires highly skilled manufacturing capabilities. PST is commonly a dry-type transformer that allows installation inside the switchroom. However, a dry-type PST is physically bigger in size due to its active part constructions and get overheated.

The dry-type PST will therefore require space in the switchroom, leading to a larger switchroom construction and increased cooling requirement. Ultimately, installing a dry-type PST often increase the total costs of the switchroom.

The Outdoor Phase Shift Transformer

A simple way to reduce footprint & lower VSD heat load in switchroom is to install the Phase Shift Transformer outdoor.

EXNOVO improves the reliability and energy efficiency of transformers through multi-year joint product development and certification effort, which resulted in the Green Safe & Maintenance free (GSM) transformer. The GSM technology combines the efficiency and reliability of Liquid Insulated Transformer, with the superior safety of Dry Type Transformer.