- +61 7 3374 2877

- Email Us

A near miss on the Westpower network triggered the development of an innovative monitoring system to detect open circuit, downed conductor faults. ConductorDown, as we have called the technology, is an application that detects a HV conductor that is broken, but only grounded on the load side of the break.

This conductor can remain energised as it is effectively back fed through the magnetising impedance of downstream transformers, with insufficient fault current to be detected by classical HV protection systems.

Voltage data collected at the low-voltage side of downstream transformers are analysed, and converted into phasors for further analysis. Machine learning techniques, involving clustering of the data and identification of key features, is then used to develop a simple predictive analytics model that can be used to give a clear indication of such a ConductorDown event.

The predictive model is applied right at the edge on ElectroNet’s PowerPilot platform and this allows for maximum selectivity and sensitivity, while minimising the response time. An alarm is transmitted using the standard PowerPilot messaging protocol, and this can either alert control room staff so they can react to and isolate the affected section of line, or can trigger an automated response through an ADMS or SCADA system.

Initial testing in Westpower’s HV test bay has shown the end-to-end system to be highly reliable with accurate positive identification rates of > 98% for such an event.

Sensing devices using ConductorDown with associated back-end systems are now being rolled out across Westpower’s network as well as other distribution networks across New Zealand.

Background

In April 2020, shortly after the initial Covid lockdown started, Westpower was alerted to a public safety incident on the network involving an open circuit, downed conductor situation where a member of the public picked up a live 11 kV conductor and threw it off the road.

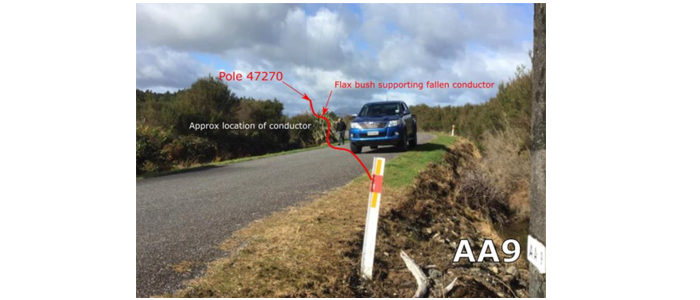

Figure 1 shows a re-enactment of the event, including an indication of where the back fed conductor was lying across the road. The break had occurred at a joint about a metre from disconnector AA9, on the pole shown at the right of the picture, and the source side conductor was free of earth.

An elderly gentleman who was driving along the road noticed what he thought was a nylon rope lying across it and stopped to pick it up and throw it off to the berm at the site, not realising that it was a live 11 kV conductor. Surprisingly, he seemed to suffer no ill effects and drove back up the road to notify the local farm manager who promptly came down to have a look.

Later analysis showed that his rubber-soled shoes and the dry asphalt on which the conductor was lying, along with the fact that there was also a lower impedance, parallel connection to earthed via a flax bush may have explained how he was able to avoid serious harm on this occasion. Upon interview, he felt that his heavily calloused hands may also have contributed to this outcome, but we were somewhat sceptical of this.

As part of the following public safety investigation, an urgent review of our protection systems was initiated to try and see why the upstream protection failed to operate.