- +61 7 3374 2877

- Email Us

New highly flexible chainflex cable saves 40% space in the e-chain and ensures reliable energy and data transmission.

Small, compact and fast: these are the demands on the new generations of motors. To this end, more and more drive manufacturers are turning to hybrid technology to save space. Therefore, Treotham offers the new expanded igus range of hybrid cables with a new cable especially for SEW motors with the MOVILINK DDI interface. Users in the material handling industry, for example, can rely on a durable cable specifically developed for e-chain applications.

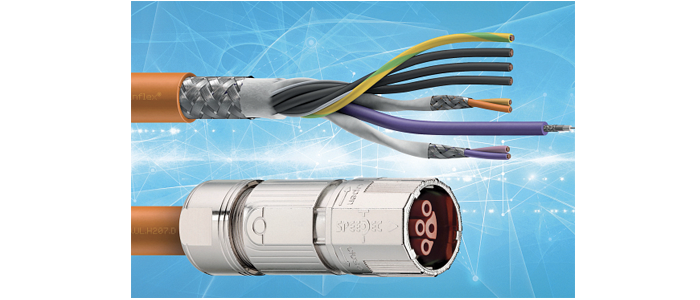

Hybrid cables for drive technology are characterised by their ability to combine energy and data transmission in one cable. The result: the number of cables required is halved. In the case of the new SEW motors with MOVILINK DDI interface, the drive manufacturer relies on a coaxial element for the data transmission of motor information. In order to be able to safely supply the compact motors with energy and data while they are in motion, Treotham provides a newly developed igus hybrid cable. “The challenge with cables with coaxial elements is that they quickly become susceptible to faults at high dynamics. That is why we have made it our task to develop a durable and flexible cable that also functions reliably in motion”, says Andreas Muckes, Head of Product Management chainflex cables at igus GmbH. To this end, the motion cable specialist can draw on its more than 20 years of expertise in the field of coaxial cables for highly dynamic applications. For the new hybrid cable CF280.UL.H207.D, four energy cores have now been combined with one coaxial core and two control pairs. By merging two cables into one, users can save 40% space in the energy chain. At the same time, the weight that has to be driven by the system is reduced, which means that less energy is consumed. The new cable with PUR outer jacket can be used for applications with a bending factor of up to 15xd and is therefore suitable for a wide range of industries: from machine tools and material handling to the automotive industry.

28 Cables for Hybrid Technology

With 28 different cable types for motors from Siemens, Beckhoff, SEW and Bosch Rexroth, Treotham has the largest portfolio of igus hybrid cables for the energy chain from stock. With the expansion of the CF280 series, igus is following the ongoing trend of hybrid technology. Treotham also offers the CF280 cable series with a PVC outer jacket as CF220. In this way, additional costs can be reduced in the hybrid cable segment. The chainflex cables can be purchased harnessed or by the metre. As with all igus cables, they ensure a guarantee of up to 36 months on the new SEW hybrid cable.

The new igus hybrid cables are available from Treotham Automation.