- +61 7 3374 2877

- Email Us

Emerald People’s Utility District of Eugene Oregon proudly serves 22,000 meters. Among the challenges of network operation in a highly forested area, Doug Barab, Systems Engineer at EPUD has successfully completed a reliability program over the last 6 years, upgrading line reclosers and substation circuit breakers. Like most senior engineers in utilities of these sizes, Doug’s responsibilities span technical and managerial considerations, everything from electrical systems design, to budgeting, leadership, and even IT technical support. Throughout this project, Doug has worked with NOJA Power to deliver switchgear solutions for his challenges. NOJA Power’s Martin van der Linde sat down with Doug Barab to discuss electricity network reliability in a US Public Utility District.

Martin: Tell us about your role with EPUD and the challenges you face

Doug: Emerald PUD serves 22,000 meters in two geographic areas that cover 560 square miles with just over 10 meters per mile of distribution line. Like many distribution utilities this size, people often wear many hats. As the System Engineer, I am responsible for the usual array of engineering tasks, such as system planning, coordination studies, substation project design, and budgeting. An important aspect related to this is that I also supervise the two-person crew that operates and maintains our substations, all the field equipment such as reclosers and regulators, and take care of all metering related activities, including the AMI system. A little less related to the engineering tasks, I also manage and operate the SCADA system, including supporting line crews, whether they need hot line tags for normal daily work, or directing their response during major outages. I also am responsible for site security and am part of the senior leadership team. I truly enjoy the variety of what I do, even if days often seem to run out of hours before they do work to be done.

Not surprisingly, the biggest challenge is finding the time for the department to get everything done. And with the wide array of responsibilities the department has, it is common for the plan for the day to change several times before we make it out of the office. We are constantly looking for new ways of doing things that can save us time and/or get more done.

Martin: How did you decide to trial NOJA Power equipment on EPUD’s network?

Doug: We knew that many of our relays and reclosers and breakers would approach the end of their expected service life beginning in 2015. Understanding that replacing them would require several years and would not come cheap, I worked with finance and the board to develop a multi-year plan to proactively upgrade equipment to mitigate the risk of outages associated with component failure. In June of that year, we issued a request for proposal to provide six to ten reclosers and controllers for each of the next five years. The proposal weighting was 40% on cost, 30% on an evaluation of the controller, and 30% on an evaluation of the software used with the controller. The goal was to find a single solution for field use, as well as our substations. This would avoid having to spend time getting familiar with multiple pieces of equipment and software applications. It would also minimise the inventory we would need to maintain, which is critical because the shop and storage is very limited in size.

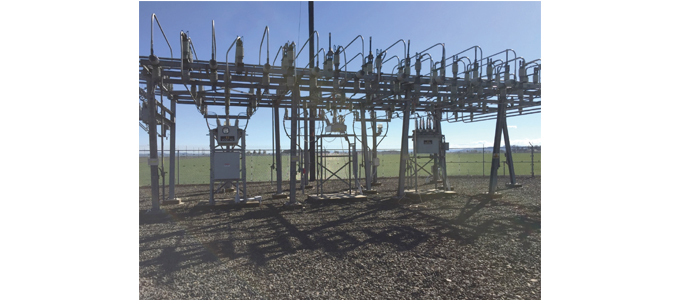

We received nine proposals. This was a big decision that would affect several groups of people within the utility. While we had experience with (or were at least familiar with) several of the manufacturers and models, we knew very little about NOJA. They provided references for several utilities who shared their experiences installing the units on poles. More importantly, though, NOJA had a demo recloser and controller on a trailer, which they brought by our shop (as well as one of our substations) so that our line crews could see it for themselves. Our linemen and substation wiremen were impressed with the build quality of the recloser and control cabinet and liked the compactness of the recloser. I spent some time with the CMS software to get a feel for how it was to use and how difficult (or easy) it would be to program the RC10 controller. (I also spent significant time with the software used by other manufacturers.)