- +61 7 3374 2877

- Email Us

Following the Victorian Bushfire Royal Commission, the Victorian government looked for innovative engineering companies that could develop new overhead conductors that would reduce the bushfire risk in Victoria. Amokabel from Sweden and Bendigo based Groundline Engineering applied for and won the grant to develop the new generation of covered conductor.

The design brief from the Victorian government was extensive and covered key areas such as high temperature fluctuations, extreme UV resistance, resistance to salt spray and industrial contaminants, abrasion resistance, as well as the ability for the products to be easily installed and maintained in remote locations.

New Generation Covered Conductor

Amokabel and Groundline developed a compliant product using Amokabel’s 25 years’ experience in the development and manufacturing of covered conductors for demanding conditions. The resulting New Generation Covered Conductor (NGCC) from Amokabel uses advances in materials technology to produce a covered conductor that is uniquely engineered for Australian conditions. NGCC is much lighter and stronger than other types of covered conductor that have previously been used in Australia (for example CCT (Covered Conductor Thick)). The fact that it is lighter and stronger allows it to be retrofitted to most existing networks without the need for expensive interpoling or other infrastructure upgrades, which are often required when using other solutions such as CCT. The addition of a unique steel (ACS) covered conductor product enables the replacement of conductors where traditionally steel wire has been used, for example in a SWER (Single Wire Earth Return) application. The Amokabel ACS product allows much longer spans than have previously been possible with covered conductor, a real advantage in difficult terrain.

In addition to the conductor itself, Amokabel supplies accessories that ensure that a complete covered system solution is achieved. This reduces the risk of fire starts by a staggering 98 percent and ensures that vegetation and our native wildlife are no longer the unwitting causes of devastating bushfires.

Outages Due to Conductor Clashing

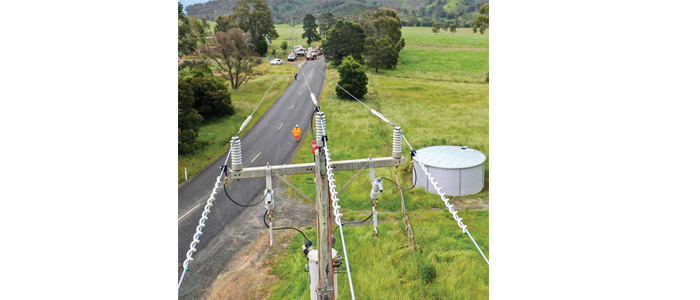

Following the successful development and approval of the complete covered solution, trials began in 2016 with one of the Victorian network operators. The trials targeted coastal areas that had previously been plagued by consistent outages due to conductor clashing. Since 2016, not a single fault has been reported on the section of line that was replaced with the Amokabel product. The products have now been installed at many other locations in Australia.

With the resounding success of the trial, Amokabel decided to open a subsidiary in Australia and founded Amokabel Australia Pty Ltd in December 2020. As part of the commitment by Amokabel to the Australian networks, Amokabel acquired a cable manufacturing business in Sydney in 2022, with the long term goal of manufacturing covered conductor in Australia.

Given that this kind of covered conductor is relatively new in Australia, experience and knowledge among the distribution network operators is quite limited. In discussions with distribution companies and early experience of those who have installed it, Amokabel’s product has shown itself able to address many of the misperceptions DNSP’s have of covered conductor.