- +61 7 3374 2877

- Email Us

Though “Dig and Drill” is the standard inspection process used for the investigation for utility poles, there are instances where the “Dig and Drill” process is extremely disruptive and/or prohibitively expensive; or simply cannot be used.

There are numerous sites within urban areas where the poles, whether timber or concrete, are partly encased in concrete or bituminous materials. They are situated in most cases on busy walkways, and inspections of these using “Dig and Drill” are very disruptive and expensive.

POLES IN PAVEMENTS

In addition to the expense, the exposing of the base of these poles below the pavements requires greater depths to dig. This can destroy the often anaerobic natural protection, and thus allow greatly increased access by moisture and oxygen, which is necessary for fungal growth. Every bored inspection hole decreases the pole integrity.

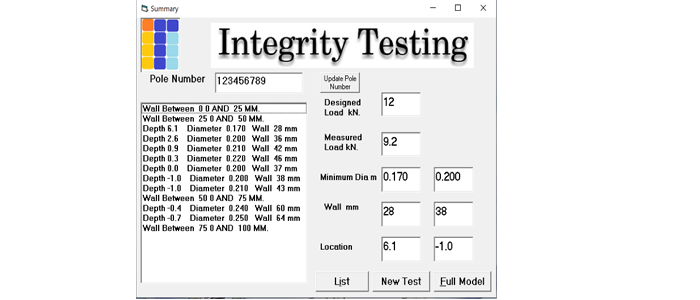

By using the single operator Mod-Shock™ test, which takes no more than several minutes per test, the operator gets ALL of the information required to make a decision on the pole serviceability. The on-site result is shown in the photo below. This includes:

Tabulated: the location of any reduced diameters and corresponding equivalent wall thickness.

Top right: the design load for the pole and the measured load on the pole plus the tip bending moment.

Bottom right: the locations of the smallest diameter and wall thickness both below and above the ground line.

Successful projects have been carried out in Bendigo (VIC), Bayside suburbs-Melbourne (VIC), Coffs Harbour (NSW), Port Macquarie (NSW), Perth (WA), and Fremantle (WA).

Steel and Mono Poles

With modern-day transmission systems, new and different pole types have been introduced into the networks, such as steel mono poles or collapsible poles, steel and concrete poles (such as used in South Australia), and non-ferrous poles.

Mod-Shock™ can test ALL of these different materials on-site. It will show the same data as above, with quick, accurate on-site answers, backed if required by a more comprehensive detailed printout for the entire length of the pole.

Successful projects have been carried out for Victrack in Melbourne (VIC), Cairns airport (QLD), and in Adelaide and surrounding suburbs (SA), Perth (WA) and Bendigo (VIC)