- +61 7 3374 2877

- Email Us

Reports of hot rope and arcing and sparking prompted the construction company to engage electrical engineers Safearth to carry out an investigation. Safearth Senior Engineer Peter Sebire discusses the investigation and findings.

The client was in the final stages of erecting a tower crane to support construction of a residential complex in western Sydney. In preparation for reeving the hook, the hoisting rope was passed through the trolley and winched to the ground. When contacted by the rigger on the ground, the rope felt hot to the touch. Heating of lifting gear, including steel wire ropes, is a significant issue as the structural integrity of the material (and hence the load rating) may be affected. A replacement winch rope is a reasonably expensive component, and can be time consuming to install. However, in this instance the main factor was that the lead time for obtaining a new rope of the required type would cause intolerable delays for the construction site. As such, the apparent heating of the rope raised some concern.

In conjunction with the sensation of heat, the rigger also observed arcing where the rope came into contact with steel reinforcing starter bars protruding from the ground. The site electrician was called and despite isolating the crane from the 3-phase supply, the arcing persisted, with more than 300V AC measured between the rope and the reinforcing. Furthermore, a test lamp connected between the rope and ground glowed dimly. However, somewhat perplexingly, numerous people had touched the rope but none had reported feeling an electric shock. Similarly, there had been no reports of electric shock at the crane, or anywhere else onsite.

ON SITE INVESTIGATION

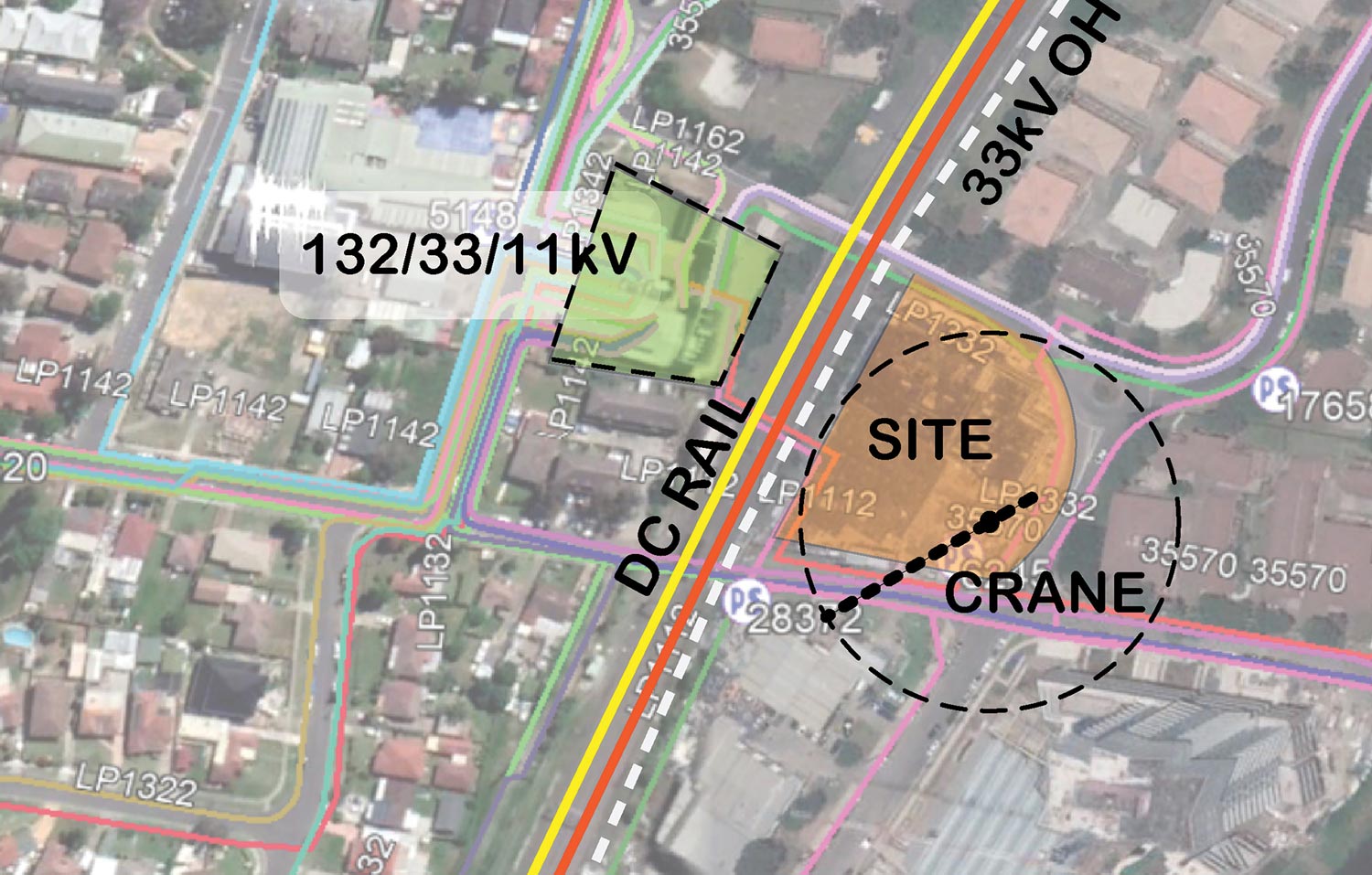

Safearth were called to investigate. In preparation, we carried out a quick desktop survey of the potential sources of electrical influence. The construction site is located adjacent to an electric rail line energised at 1500V DC with parallel 33kV overhead lines, and within 100m of a major 132/33/11kV substation. 11kV overhead lines ran along the street. We were also aware of underground cables that had been damaged some time before, though the local utility confirmed they were now de-energised and out of service.