- +61 7 3374 2877

- Email Us

As digitalisation progresses in all industries, the use of online monitoring solutions is becoming increasingly important – including for transformers. However, despite their numerous advantages, there are still misconceptions that are often based on experience with outdated products and do not take into account the latest developments, such as the implementation of AI. Concerns span from perceived high costs and the management of extensive data, to doubts regarding reliability, as well as concerns involving cybersecurity.

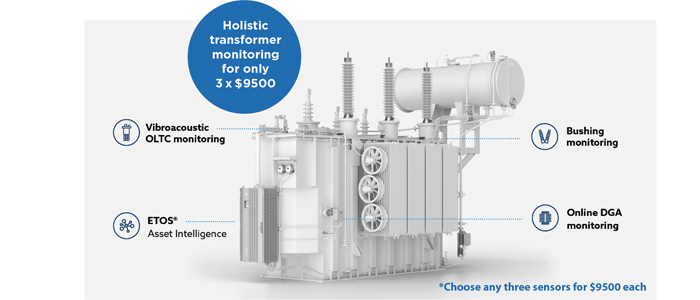

Installing online monitoring for transformers is a costly adventure

Retrofitting an online monitoring system is often associated with a high initial investment. Depending on the equipment selected, this may be correct. However, especially for standard applications, it makes sense to focus on the most critical components. As CIGRÉ WG A2.37 has established, active parts, high-voltage bushings and OLTCs are responsible for over 90% of transformer failures. With ETOS® these three critical transformer components can be monitored for only 3 x $9500. All included sensors (see image above) are easy to retrofit and enable comprehensive condition monitoring on a low budget.

ETOS® enables holistic transformer monitoring for only

3 x $9500.

Online monitoring leads to an unmanageable amount of data to be analysed

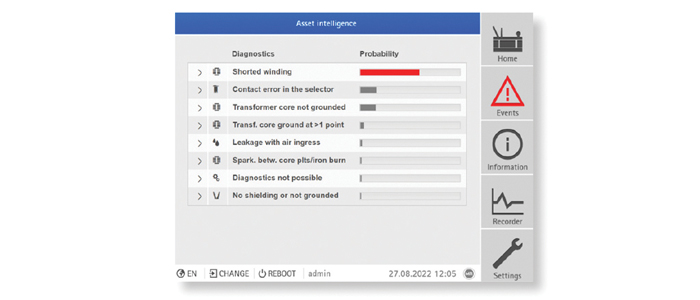

Instead of leaving you to evaluate all the collected sensor data on your own, ETOS® acts as a central data processing system on each transformer. With Asset Intelligence, it features an algorithm that analyzes the data from all installed sensors together. Based on research data and the expertise of our transformer specialists, Asset Intelligence identifies the most likely causes of faults, speeding up fault diagnosis and suggesting effective counter measures. Here‘s the key: the more sensors are connected, the more accurate the diagnosis, enabling better and faster remedial action.

Analysing data has never been so easy.

Finding qualified personnel is difficult these days

Indeed, online monitoring requires personnel who have the time to analyse the gathered data. However, with Asset Intelligence analysis efforts are reduced to the bare minimum. On the other hand, a time-based maintenance strategy means unnecessary service jobs where you only record conditions on a single day. The rest of the time the condition of your transformer is unknown. For only 3 x $9500, ETOS® provides a 24/7 condition overview of the most critical transformer components. Through trend analysis you get an early indication of anomalies allowing you to schedule maintenance when it‘s truly necessary and maximise availability without compromising on safety.