- +61 7 3374 2877

- Email Us

CSE Uniserve is building a safer, more productive world through the integration of intelligent system solutions. Australia’s trusted supplier of protection, automation, communication, and condition monitoring solutions, CSE Uniserve’s specialist integrators, engineers and project managers work rapidly to build better processes in environments that require reliable and deliberate connections, to ensure minimal disruption and dependable performance.

The challenges of escalating maintenance costs, risks associated with accessing transformers and appointing staff with the right skillsets to undertake scheduled site maintenance in a saturated job market have made remote inspection solutions more of a “must have” rather than a “nice to have” business capability.

In partnership with SWI, CSE Uniserve provides world-leading solutions for monitoring and management of critical assets as well as the associated design, implementation and support services.

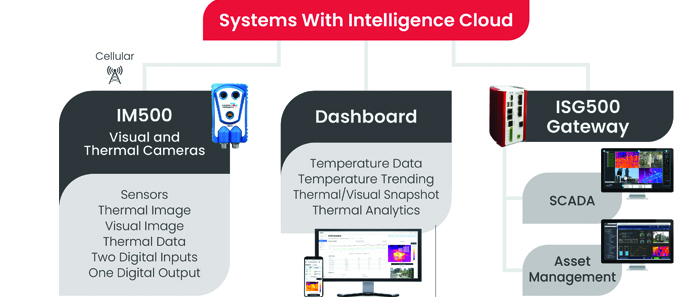

Industrial IoT Monitoring Platform

Whilst there are many SCADA based solutions on offer, the Systems With Intelligence™ (SWI) Industrial IoT Monitoring Platform provides a window into asset health. Whatever the device may be, the SWI platform integrates leading, industry-standard tools that collectively deliver the operational insights necessary for the success of a progressive business. A true differentiator in the market, SWI delivers a flexible, secure, self-managed, cloud-based analytics platform that can integrate thermal and visual inspection modules, such as the IM500. By utilising the SM500 sensor module at remote sites, customers can also integrate a wide variety of third-party sensor modules for monitoring and collecting asset health data via Modbus on those sites.

Key Solution Benefits

The implementation of the IM500 industrial IoT module delivers thermal and visual inspection capabilities with an interface to other sensors providing safety, environmental and quality monitoring signals. The signals detect anomalies and securely transmit these signals to the Monitoring Platform to provide automatic warnings. When integrated with the dedicated cloud Monitoring Platform, the IM500 is the perfect tool for preventive and predictive maintenance.

Features- IM500

Touchless Inspections Deliver Return on Investment.

A utility customer was performing thorough periodic substation inspections that included the enclosed connections on the low-voltage side of the transformer. To do the inspection, the transformer had to be powered down and temporary alternate power trucked in. The enclosure is accessed through a bolted hatch to enable the technician to visually inspect the connections, however, the connections could not be thermally inspected with no current flowing through the connection points. Due to the time and expense required, the inspections were performed on an infrequent basis, opening the possibility of missing problems that could lead to more expensive failures and outages.