- +61 7 3374 2877

- Email Us

MONTESTO 200 is our portable system for temporary online PD monitoring and trending insulation status between diagnostic checks.

In this article, we interview our MONTESTO 200 Product Manager Bogdan Gorgan about how our temporary online partial discharge (PD) monitoring system can help you to keep an eye on PD activity for however long you need to in a wide variety of high-voltage (HV) equipment. He also presents a case study about how the MONTESTO 200 was used for a two-week in-service assessment of the insulation condition in an older rotating electrical machine.

OM: Bogdan, could you explain the importance of performing PD measurements and when are they typically performed?

BG: “PD measurements are recognised worldwide for insulation diagnosis and are usually a required part of the acceptance testing procedure for most high-voltage (HV) equipment. Based on the absence or presence of PD activity caused by insulation defects discharging during routine tests, onsite tests, or periodic in-service inspections throughout the service lifetime, conclusions can be drawn about the actual condition of the dielectric insulation system. Due to on-going aging of the insulation systems of HV components in service, onsite PD testing and diagnostic methods are being increasingly used in condition monitoring on a temporary short-term or permanent long-term basis. OMICRON offers solutions for all of these PD testing and monitoring applications.”

OM: What is the difference between offline and online

PD testing?

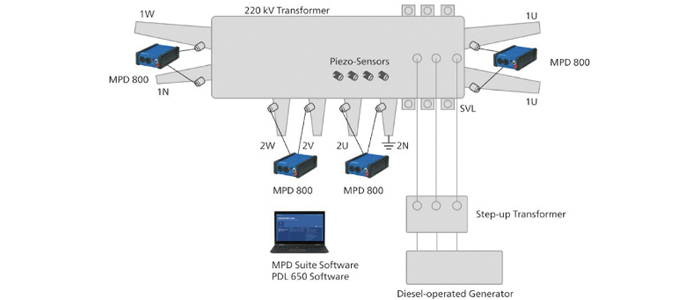

BG: “PD can be measured offline, such as with our MPD 800 PD measurement and analysis system. In this case, the asset is energised by a separate HV source. PD can also be measured or monitored online while the asset is connected to the electrical grid and in operation – either with the MPD 800 or our MONTESTO temporary PD monitoring system using permanently-installed PD sensors and a terminal box.”

OM: Please explain what is meant by online PD monitoring and how it differs from online PD testing.

BG: “PD monitoring is the process of observing and trending partial discharge activity over a period of time to assess insulation condition, identify potential weak spots and determine the level of risk for a dielectric failure. The information from the PD sensors – including bushing tap sensors, coupling capacitors, High-Frequency Current Transformers (HFCTs) as well as Ultra-High Frequency (UHF) sensors – is synchronously measured by the multi-channel acquisition unit and stored in a database. The synchronicity between the channels enables the separation of noise and PD signals. The data is trended over the specified period of time and compared with user-defined thresholds to determine whether a problem is developing or not.

When it comes to temporary PD monitoring, an online PD measurement is continued for few days, a week, month or even up to a year to obtain a more detailed picture of potential progressive deterioration in the electrical insulation.