- +61 7 3374 2877

- Email Us

The following experience centered on a seventeen-position resistive-type On-load Tap Changer (OLTC) that is installed on the HV side of a three-phase YNd1, 25 MVA, 132/11.5 kV transformer. This load tap-changing transformer is operated by Electric Power Transmission Network in the City of Karbala, Iraq.

The maintenance team at the Electric Power Transmission Network in the City of Karbala performed routine electrical tests on the transformer including: winding resistance measurements (WRM), transformer turns ratio (TTR), short circuit impedance (SCI), excitation current, and line-frequency power factor (a.k.a. dissipation factor or tan delta).

With the TRAX instrument, they can also perform advanced testing including: magnetic balance, Frequency Response of Stray Losses (FRSL) and OLTC Dynamic Resistance Measurement (DRM) tests.

Only the DRM test results clearly flagged a deficiency in Phase B of the OLTC, which was not observed in static measurements. Static measurements are those that are performed while the OLTC (and DETC) is stationary at each of a number of selected tap positions.

Dynamic tap changer measurements, such as provided by a DRM test, are critical to assess a resistive-type OLTC’s bridging or ‘transition’ components, which only appear in a test circuit during the OLTC’s transition from one tap position to the next. A resistive-type OLTC does not use its bridging state as a viable tap service arrangement/position, so these components never appear in the test circuit of a static measurement.

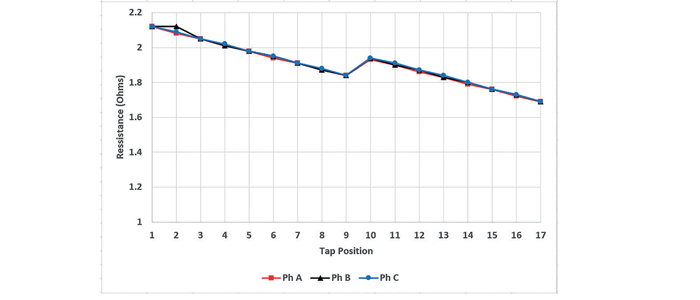

In this case, the DC WRM on all tap positions (a series of static measurements, Figure 1) shows a very small variation (around 0.2 %) between the three phases and for all taps. This is well within the generally agreed, maximum allowable variation of 2 – 3 %.

Looking at the TTR measured values (Figure 2), it was observed that all phases and all taps have a measured ratio well within the generally agreed acceptance value of 0.5 %.

The Line-Frequency (LF) power factor (PF), or dissipation factor (DF), and NB DFR (narrowband dielectric frequency response) test results (Figure 3) were acceptable. No notable insulation degradation was indicated.

Advanced OLTC testing was carried out with the Dynamic Resistance Measurement application in the TRAX SW. During the transition from one tap position to the next, the current drops and that is represented by the ‘ripple’, which expresses the maximum amount that the DC current decreases as a percentage of the test current. The ripple is normally plotted for all phases and taps as presented in Figure 4.

The ripple graph from phase B may be different compared to the graphs of phase A and/or C due to different induction.

In this case, the difference in ripples between phases combined with the variance of ripples within Phase B indicate a problem for Phase B.

DRM analysis provides even more insight than comes from measuring the ripple alone. In a ‘true’ DRM test, the transition resistors’ values are determined with great precision. Figure 5 shows the dynamic resistance for transition 12-13 for Phase C and Figure 6 shows the DRM for transition 13-12 for phase B. Notice the difference in scales on the y-axis (in ohms) of both graphs.

Figure 5 is a typical transition DRM response for a 2-resistor switch that has been in service for some time. Resistance values and transition times for both resistors are similar.