- +61 7 3374 2877

- Email Us

The expansion of electrical grid connections has increased the use of Sulphur Hexafluoride (SF6). It is widely used in the electrical industry due to its effective insulating properties. The cheap, non-flammable, odourless, synthetic gas has been used as an insulating medium for gas-insulated switchgear (GIS) since the early 1950s.

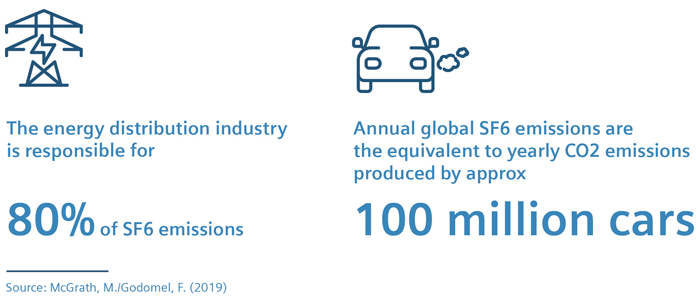

SF6 is also the strongest known greenhouse gas. Over a period of 100 years, its contribution to the greenhouse effect is 22,800 times greater than that of carbon dioxide (CO2). Energy providers are challenged to adopt and implement gas-free solutions more rapidly to decrease emissions, their effects on the environment, and to meet the latest legislation requirements.

For medium voltage, SF6 is commonly used for gas-insulated switchgear due to its excellent dielectric insulation and arc-quenching properties. However, SF6 has a high greenhouse effect if released into the atmosphere. Technology company Siemens has been engaged in intensive research for SF6 alternatives for many years. As a result, Siemens combined Clean Air for gas insulation with proven vacuum-interrupter technology. This, including intelligent digital solutions, forms the new portfolio “blue GIS”, now available for the Australian market. Portfolio Professional Xuehua Lu states, “I believe this is the right way into a sustainable future of medium voltage switchgear.”

Some of the critical advantages of blue GIS:

Environmentally friendly with no use of F-gases or chemical additives, using clean air technology, give a GWP (Global Warming Potential) <1 and ODP (Ozone Depletion Potential) of 0.

Safety: Clean Air is non-toxic, non-flammable, extremely stable and has a very low boiling point (insulating medium doesn’t liquefy).

Cost-efficient F-gas-free insulation with minimum requirements for training, transportation, installation, and operation. Also, no documentation or reporting requirements and no gas recycling required making Clean Air the most cost-efficient arc quenching medium to be used in medium voltage switching technology.

The biggest millstone of the F-gas-free journey is the load-break switch (LBS) development, which is an essential contribution to its F-gas-free product portfolio. This three-position LBS (Figure 1) combines a make-proof switch-disconnector, a make-proof earthing switch and a vacuum interrupter in a parallel current path (called “auxiliary path”) for arc extinguishing, which are all actuated by a single operating mechanism. The arc quenching function of an LBS is only needed for a few milliseconds during breaking. It is realised with a small vacuum interrupter in the auxiliary path, which does not carry continuous or short-circuit currents. Making of the main circuit and making of the earthing circuit is performed by a three-position contact blade system.