- +61 7 3374 2877

- Email Us

The risks of arc flash and arc blast are a significant health and safety concern in the workplace for electrical workers.

Arc faults arise when current flows through the air between phase conductors, phase to neutral or from phase to earth. These connections can occur during high-risk activities, such as operating or racking of circuit breakers or contact across terminals from tools or equipment, a breakdown in insulation, or from a build-up of contaminates such as carbon or dust. An arc fault could be described as an unexpected, electrical short circuit in the air that produces an arc and associated by-products. When arc faults occur, the resulting energy released may be enough to seriously burn or otherwise injure nearby persons, ignite flammable materials including clothing, and cause significant damage to plant and equipment.

Significant development has occurred in engineering newly manufactured switchgear equipment with best-in-class arc fault protection, insulation, and isolation, however, there remains a large volume of installed industrial equipment without these engineered solutions, and we may be decades from cycling this equipment out of service. As such, we do rely on effective PPE as a last line of defense to prevent burns during an arc flash incident and it’s an area where innovative manufacturers are focusing efforts to improve wearability, comfort and breathability that ultimately leads to a safer and more productive workforce.

It stands to reason that arc flash PPE design that considers the operator, their comfort, the working environment, and the tasks to be completed will inherently provide better safety and productivity outcomes. Much of the first-generation Cat 4 PPE suffered from poor fitment, bulky and heavy materials, a lack of breathability and challenges with reach and bending tasks. By collaborating with industry PPE users to understand and solve many of the key complaints associated with earlier generations of arc flash PPE, National Safety Apparel (NSA) has developed and launched their industry leading ArcGuard Performance line of Cat4 (40cal/cm2) PPE.

Being an aggressive innovator focused on user comfort has allowed NSA to position as the leader in arc flash PPE design. In collating customer feedback, three key characteristics stood out as critical to manufacturing the most comfortable PPE in the market. Cat 4 PPE needs to be lightweight, breathable and moisture wicking. NSA designed their ArcGuard Performance garment with this in mind, and through customer feedback and clever design, this product also delivers on step changes in fit and mobility, improved visibility and ease of adorning PPE.

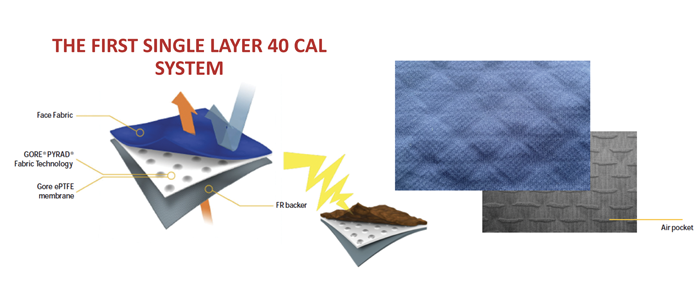

The ArcGuard performance garments utilise a GORE®PYRAD® single layer fabric system weighing only 9.5oz/yd (322gsm). Lighter weight materials reduce fatigue and the distraction of discomfort, allowing the wearer to focus on the task at hand and maneuver as the work requires. The new GORE®PYRAD® system rates as very breathable per the RET Hohenstein Rating System. The Hohenstein institute is a globally recognised expert in textile science, utilising human subject trials and laboratory test methods to determine how breathability translate to comfort for the wearer.